Band Heaters are used to heat cylindrical surfaces. Band Heaters can be manufactured in countless different configurations. Southern Heat offers a range of construction styles including mica insulated, ceramic insulated, and mineral insulated band heaters.

Band Heaters are used to heat cylindrical surfaces. Band Heaters can be manufactured in countless different configurations. Southern Heat offers a range of construction styles including mica insulated, ceramic insulated, and mineral insulated band heaters.

Browse through our products below or Contact Us to discuss your project.

Band Heater Survey Checklist – PDF

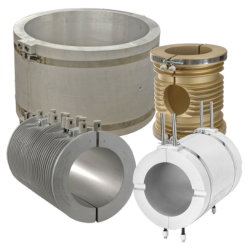

Ceramic Band Heaters

Ceramic Insulated Band Heaters can meet the demand for energy conservation & operation efficiency. They are capable of generating higher temperatures essential to process today’s resins. Electrical energy savings are achieved by using a 1/4″ thick ceramic fiber insulating blanket, reducing power consumption by 25 to 30%. Because of the low thermal conductivity of the ceramic fiber insulation, when the external surface temperature of the heater is ~400°F, the inside surface temperature is ~1200°F.

Special Features: Fully flexible heater that conserves electrical energy

Mica Band Heaters

Mica Band Heaters are a reliable band heater that can perform at the higher operating temperatures [up to 900°F (482°C)] essential to process high temperature resins, providing long, efficient service necessary for today’s high productivity of plastic extruders, injection and blow molding machines. It is a proven heater design for good life efficiency and dependability. It assures maintaining the lowest winding temperatures possible, keeping a low-mass heating element assembly for fast heat-up and quick thermal response to controls.

Special Features: Most economical, versatile and commonly used

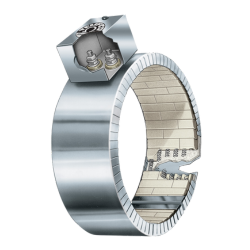

Maxiband Heaters

Maxiband Heaters

Maxiband Heaters can be designed as Heat and Cool, Heat Only or Cool Only. The channels in the extruded aluminum track are precisely sized to accept a .315 diameter tubular heating element and provide an excellent heat sink for rapid heat transfer and good temperature uniformity.

Special Features: Rugged contamination-proof and excellent heat transfer

Mineral Insulated Band Heaters

Mineral Insulated Band Heaters

Mineral Insulated Band Heaters are the solution for applications that require high watt densities and/or high operating temperatures. Mi-Plus band heaters are capable of temperatures up to 1400°F (760°C) and watt densities up to 150W/in2 (23.25W/cm2). The recommended maximum watt density for a specific application will depend on the heater size and its operating temperature.

Special Features: Capable of high temperatures and high watt densities

Tubular Band Heaters

Tubular Band Heaters can perform under the most adverse conditions. Highly recommended for heating applications where premature nozzle band heater burn-out on plastic injection molding machines is a constant problem due to contamination from plastic overflow or other contaminants. They are proven to be very effective for processing Teflon® and high temperature resins.

Special Features: Rugged contamination-proof construction.

Cast-In Band Heaters

Cast-In Band heaters can be made with one of two cooling methods: Liquid-cooled or Air-cooled. Used heavily in plastics extrusion processes, the cooling function within our cast-in band heaters is important for maintaining the proper temperature of the barrel.

Precision machining of the band heater’s inside diameter yields superior heat transfer between the heater and machine barrel and is finished to customer specifications.