Cast-In Heaters consist of a cable heater that has been cast into a block. Cast-In thermal components are available in aluminum and bronze alloys and are highly customizable. Cast-In Heaters can be liquid cooled or air cooled. For more information about our updated, efficient, and cost-saving air cooled Cast-In Heaters, check out Shroud Systems.

Cast-In Heaters consist of a cable heater that has been cast into a block. Cast-In thermal components are available in aluminum and bronze alloys and are highly customizable. Cast-In Heaters can be liquid cooled or air cooled. For more information about our updated, efficient, and cost-saving air cooled Cast-In Heaters, check out Shroud Systems.

Browse through our products below or Contact Us to discuss your project.

Cast Aluminum Survey Checklist – PDF

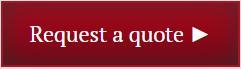

Cast-In Band Heaters

Cast-In Band Heaters are manufactured in aluminum alloys because this material provides very good thermal conductive properties. For applications requiring higher operating temperatures and/or higher watt densities, bronze alloys can be used. Cast-In Band heaters can be made with one of two cooling methods: Liquid-cooled or Air-cooled. Used heavily in plastics extrusion processes, the cooling function within our cast-in band heaters is important for maintaining the proper temperature of the barrel.

L-Shaped Cast-In Heaters

The “L” Shaped Cast-In Heaters are used on square and rectangular twin screw extruder barrels in compounding and plastic resin manufacturing applications. Due to high shear rates, extreme operating temperatures and high watt densities are frequently encountered. These “L” shaped heaters are manufactured in bronze or brass alloys, which are capable of withstanding high temperatures at higher watt densities.

Shroud Systems

These highly engineered heating and cooling systems offer a very efficient means to heat and cool the barrels of plastic extruders. They provide cooling efficiencies equal to or better than conventional liquid cooled cast-in aluminum band heaters. These Shroud Systems are self-contained and can be supplied as turnkey ready-to-go, requiring minimum labor and installation cost, and drastically reducing downtime and maintenance upkeep compared to conventional liquid cooling and heating cast-in band heaters.

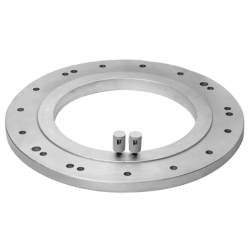

Cast-In Ring Heaters

Cast-In Ring Heaters provide an excellent means of applying extremely uniform heat to limited access application areas. Cast-In Ring Heaters are frequently used in Blown Film Die, Extrusion Die, Screen Changer and Extruder Barrel Adapter applications where long life and minimal maintenance concerns are prevalent. As a standard, Cast-In Ring Heaters are generally manufactured in aluminum because of its superior thermal conductivity. For higher temperature or high watt density requirements, bronze or brass alloys can be used.

Cast-In Platen Die Heaters

Plastic die applications are highly temperature sensitive and require extreme heater uniformity and reliability. Cast-In Platen Heaters are widely accepted as the industry standard for heating critical, temperature-sensitive plastics processing downstream equipment. Optional cooling tubes can be cast-in to more precisely regulate the temperature of your process. The result is a highly efficient, uniform heater which, if used properly, can be expected to provide years of trouble-free service.