Infrared Heaters can deliver infrared radiant heat energy to concentrated areas at a very fast rate with individual heaters or heater arrays. Your infrared heater solution may be best suited to a peak Long Wave Length Element (ceramic), Medium Wave Length Element (quartz cassette) or Short Wave Length Element (quartz halogen/tungsten). Your custom solution may even combine many types of infrared heating elements together. Southern Heat can help you find the perfect solution for you needs.

Infrared Heaters can deliver infrared radiant heat energy to concentrated areas at a very fast rate with individual heaters or heater arrays. Your infrared heater solution may be best suited to a peak Long Wave Length Element (ceramic), Medium Wave Length Element (quartz cassette) or Short Wave Length Element (quartz halogen/tungsten). Your custom solution may even combine many types of infrared heating elements together. Southern Heat can help you find the perfect solution for you needs.

Browse through our products below or Contact Us to discuss your project.

Long Wave Ceramic Elements

Ceramic heaters are the most efficient infrared emitters on the market because they operate best at temperatures ranging from 300° to 700° Celsius (575° – 1292° Fahrenheit). Subsequently, they produce infrared wavelengths in the 2-10 micron range. Many materials and plastics absorb infrared best in this range. Long Wave Ceramic Elements may be Trough Elements or Hollow Elements.

Medium Wave Quartz Elements

Quartz Infrared Heating Elements provide medium wave infrared radiation. They are used and preferred in industrial applications where a more rapid heater response is required. They have a broad emission spectrum from around 1.4 to 8 microns, slightly shorter in wavelength than ceramic elements. Pillared quartz elements have the same mounting fixture as ceramic elements allowing easy replacement.

Short Wave Tungsten / Halogen Elements

Tungsten and Halogen Heating Elements offer a range of benefits. Reaching high temperatures within seconds, the quartz tungsten heaters are operated at temperatures up to 1500°C (2732°F) as well as a wavelength emission of 1.6 emissions. Halogen heaters are filled with halogen gas reaching a temperature of 2600°C (4712°F). These emitters heat up and cool down within seconds making them particularly suitable for systems requiring short cycle times. Heat output is also very high making these heaters useful in high heat demand or in fast moving processes.

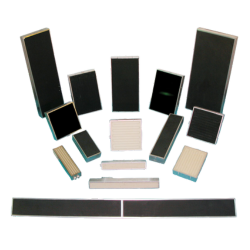

Infrared Radiant Panels

IR Panels are carefully designed to provide uniform heat distribution. The refractory material is backed by layers of insulation to minimize back heat loss. The standard housing is made of heavy gauge aluminized steel. Optional housing materials include 304 Stainless Steel. The backside of the housing has a terminal box for electrical wiring with ceramic terminal bushings and stainless steel screw terminals. Options available include: Standard quartz tube thermowell and clamp on the short side, standard Type K or J 1/8″ diameter thermocouple probes and various back mounted thermowell/thermocouple combinations.

Infrared Ovens

Long Wave Ceramic Infrared Ovens and Medium Wave Quartz Infrared Ovens are designed with your market in mind, the variations in platen size and element type available depend on the area to be heated and the application or target material involved. We can test your material and recommend the most energy efficient industrial heaters and processing solution for your application. IR Ovens can operate stand alone of be integrated into an existing line.