Authored By: Isabel McCord

Heat Smarter, Not Harder: Tips for Extending the Life of Your Band Heater

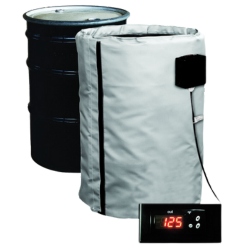

Band heaters are essential to plastic extrusion and molding, working hard behind the scenes to keep things running smoothly. While they’re built to withstand intense heat, they’re not indestructible. A little care goes a long way in extending their lifespan, improving system efficiency, and avoiding costly downtime.

Here are some simple, effective tips to help your band heaters go the distance:

- Moisture Is the Enemy

Band heaters and moisture go together like oil and water—literally.

If a heater sits in a humid environment for too long, it can absorb enough moisture to blow out the moment it’s powered on. And we’re not just talking puddles—damp lead wires or insulation can also trap moisture.

💡 Pro Tip: If your heater’s been exposed to moisture, preheat it at a low temperature to safely dry it out before applying full power.

- Keep Oil Where It Belongs (Hint: Not on Your Heater)

Oils and other organic materials might seem harmless, but at high temperatures, they can carbonize and become conductive. That’s a major hazard for your heater.

Even if oil only touches the lead wires, it can be drawn inside the heater and cause failure.

Bottom line: Keep your heater clean, dry, and far from spills.

- Avoid Overheating—Your Heater Will Thank You

Band heaters thrive on balance. Run them too hot, and you’ll burn through their lifespan.

Here’s how to keep them in the sweet spot:

- ✅ Ensure a snug fit. Gaps between the heater and barrel reduce efficiency and force the heater to overwork. Retighten the clamping strap after the initial heat-up for a better fit.

- ⚡ Choose the right wattage. Bigger isn’t always better. Excessive wattage causes more frequent cycling and unnecessary heat—both of which wear out your heater.

🛠️ Quick Fix: Retighten the heater after its first use to improve heat transfer and longevity.

- Minimize the On-Off Marathon

Frequent cycling wears out your heater fast. Every time it powers on and off, the element wire oxidizes. Over time, this leads to thinning, cracking, and eventual failure.

Reduce unnecessary cycling by:

- Using a well-calibrated temperature controller

- Avoiding oversized heaters

- Checking for sticking switches or faulty sensors

🎯 Consistent operation helps your heater last longer—and saves you from surprise breakdowns.

- Handle With Care

Band heaters may look tough, but they’re not built for rough treatment.

🚫 Don’t pull them by the lead wires.

🔧 If you’re working with post terminals, use two wrenches—one to hold the base, the other to tighten.

Also, minimize vibration or movement during use. Excessive jostling can damage internal components over time.

- Get the Specs Right

We know—it’s not the most exciting part. But choosing the right heater for your system makes all the difference.

Common mistakes to avoid:

- Incorrect size or shape

- Mismatched wattage or voltage

- Poor sensor placement

- Using the heater outside its intended application

Take time to spec it properly now, and you’ll save yourself headaches (and replacement costs) later.

Wrapping It Up (Before It Burns Out)

Your band heater doesn’t need constant attention, just the right kind. Avoid moisture, keep it clean, reduce cycling, handle it with care, and make sure you’ve got the right fit for the job. Do all that, and it’ll keep powering through—even when the plastic pellets start flying.

💬 Have questions or need help finding the perfect band heater? We’re just a message away.

Watlow DIN-A-MITE A Power Controller

Watlow DIN-A-MITE A Power Controller